Without a standard, there is no long term sustainability.

Improvement begins with the development of a system for organizing the workplace and the processes to create a common language to allow employees to:

- Quickly identify process anomalies and make them obvious to everyone.

- Constantly identify improvement opportunities.

- Make everybody’s work easier.

- Promote knowledge sharing and skills development.

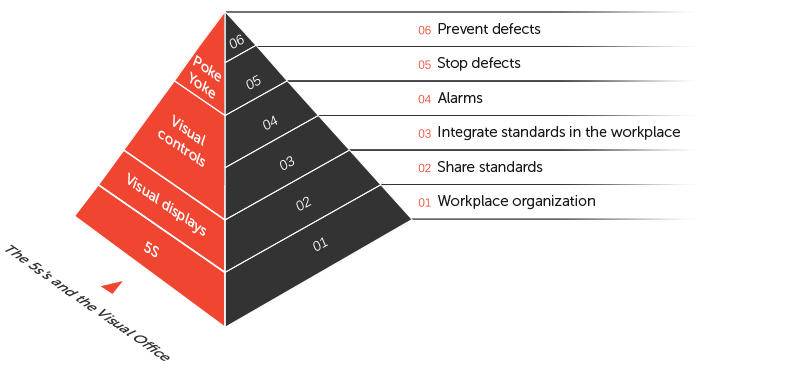

Setting operating standards and creating visual displays and controls enable people in a department to obtain the information they need in less than a minute. Performance levels are immediately visible.

Result: a clean and spotless office in which:

- Document flows are entirely visible.

- Workplace layouts and ergonomics enable users to easily reach every document or object needed.

- Cabinets/storage space are tidy and labelled in a completely visual way.

- Supplies and consumables are stored with min/max levels for ease of replenishment.

The definition and implementation of visual standards, part of the 5S system, is the result of a rigorous analysis and improvement process.

Simplify, organize and standardize to save time!

5S is a simple-to-understand methodology for organizing the workplace, with a significant impact on a department’s daily efficiency. 5S is the starting point for continuous improvement in the office. It is integrated into the Lean Office implementation road map.

Productivity has developed a practical 5S and Visual Control training program adapted to every type of office environment: back office, purchasing, accounts payables/receivables, cash management, sales & marketing, HR, legal and financial functions.