Lean production means continually eliminating waste and perfecting processes so that you can maximize value for customers and employees, and in the largest sense, society as well. That can’t happen in an organization unless all employees (leaders and frontline associates alike) are aligned, making internal and external customers the priority every day.

In any company that (1) has equipment, (2) involves people, and (3) is serious about maximizing value by making a lean transformation, total productive maintenance (TPM) is essential. Far from a management fad, TPM has deep roots; it began when preventive maintenance approaches in the U.S. were expanded upon in Japan as the Toyota Production System was developing there.

The roots and purpose of TPM

Seiichi Nakajima, the individual most credited with the development of TPM, began researching preventive maintenance techniques as a young consultant with the Japanese Management Association.

He introduced PM to Japan in 1951. As more advanced maintenance methods such as corrective maintenance and productive maintenance were adopted, they were integrated and adapted to Japan’s industrial environment.

In Japan, the Toyota Production System was evolving. Total quality control and small group activities such as quality circles and 5S teams were gaining momentum. “Zero defects” became the ideal for manufacturers. These efforts set the stage in the late 1960s and early 1970s for the introduction of total productive maintenance (TPM). The “total” in TPM means total effectiveness, total maintenance system, and most importantly, total participation of all employees. Nippon Denso, a supplier to Toyota, was the first major adopter.

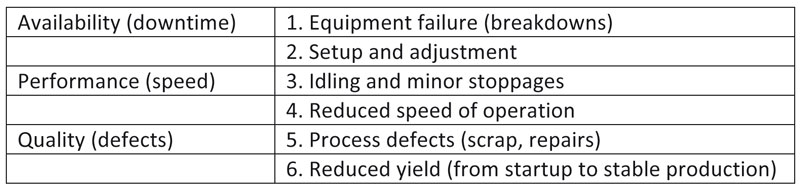

In Nakajima’s Introduction to TPM, (published in Japanese in 1984 and in English by Productivity Press in 1988) we find the most basic definition: “Total productive maintenance (TPM) is productive maintenance carried out by all employees through small group activities.” (p. 1) Nakajima defines the dual goals of TPM as “zero breakdowns and zero defects.” (p. 2) The aim is to maximize the overall effectiveness of equipment by eliminating what were defined originally as the six big losses. (They have over the years expanded to different versions with varying numbers of losses.)

The Six Big Losses

TPM and lean production

According to Nakajima, the idea of TPM originated during a visit he made to Toyota. TPM’s purpose, he writes, “corresponds to the absolute elimination of waste in the Toyota production system [TPS].”

He illustrates his point by mapping the relationships between the six big losses and the core elements of TPS: flow, defect elimination, just-in-time production, zero inventory, kanban, leveling, quick changeover, standard work, autonomation, and visual controls. The many interrelationships cross and overlap, like a better-organized version of a spaghetti diagram. Nakajima sums up these relationships in a few words:

“In striving for zero breakdowns, TPM promotes defect-free production, just-in-time production, and autonomation. It is safe to say that without TPM, the Toyota production system could not function. The fact that Toyota-related companies are rapidly implementing TPM confirms its importance in the Toyota production system.” (p.16)

In the Shingo-Prize-winning book The Evolution of a Manufacturing System at Toyota, (published 15 years after the original Japanese edition of Nakajima’s Introduction), Takahiro Fujimoto examines the ongoing evolution of Toyota’s manufacturing system in the 1980s and 1990s. He counts TPM among the basic routines of Toyota-style production systems (p. 293), and points out that although Toyota’s maintenance organization has been “centralized as a separate section at each plant,” there is

“a tendency…to decentralize it at the process level…. Maintenance people used to be in charge of maintenance and operation of automated equipment, but now direct line workers are trained to handle minor fixes and preventive maintenance on their own equipment under the total productive maintenance (TPM) arrangement.” (p. 242)

Reliable equipment is essential for reliable and stable processes. Stability is a foundational element of TPS/lean. And TPM is a fundamental set of practices for any organization seeking to implement a Toyota-like system that emphasizes reliability, quality, and continuous learning.

The fundamental metric of TPM

The core measure of TPM is overall equipment effectiveness (OEE), which tells you how effective a piece of equipment is in the context of your value stream. The formula for calculating OEE combines the various losses into one comprehensive measure:

OEE = Availability rate × Performance rate × Quality rate

Because OEE packs a lot of essential information into one number, it’s powerful; but there has also been persistent confusion about how to use it appropriately. The wielding of powerful metrics can be a tricky feat; it’s not always easy to safeguard against them becoming numerical targets abstracted from the reality of the workplace. As W. Edwards Deming cautioned:

“Eliminate slogans, exhortations, and targets asking for zero defects or new levels of productivity. Such exhortations only create adversarial relationships, as the bulk of the causes of low quality and low productivity belong to the system and thus lie beyond the power of the work force.” (Deming’s 10th principle, Deming Institute)

The point is to maintain focus on what’s actually happening in processes and systems and to improve—not to focus on fixing a number. Numbers follow the process. Results help us track progress, but when the focus shifts to the numbers themselves, the true nature of problems can be obscured. That’s when setbacks happen and real improvement gets derailed.

Tips on OEE, and the metrics of TPM

We’ll bring you more in-depth information on how, when, and where to use OEE effectively in an upcoming white paper (drop us a note to be notified when it’s available). For now, here are a few tips:

- “OEE is a way to assign numerical value to opportunity,” as Ellis New, senior consultant at Productivity Inc., says. Think of it as an improvement metric.

- OEE provides an ideal structure for teaching about the nature of losses, and changing mindsets.

- Use OEE to analyze problems and opportunities at specific constraints in your process, not as an aggregate key performance indicator (KPI) for a value stream or plant.

- Use simpler metrics (such as build to schedule), to track how production is going. Build to schedule won’t reveal much about losses or improvement opportunities, but it’s easier to calculate and understand as a gauge of production status.

- Always remember that it’s not about the absolute number, it’s about the improvement. Use OEE conscientiously and in context, as a “yardstick” for improvement (not as a stick with which to punish people).

The benefits of TPM will show up in your lean transformation “scorecard.” In companies that make effective lean transformations we expect to see results that include significant reductions in lead times, increases in inventory turns, productivity gains, reductions in defects, increased working capital, increased growth, and that least tangible but most important one of all—a team culture in which everyone is working on continuous improvement. Focus on TPM as an ongoing process, and you’ll see the results in all those areas.

References:

- Deming Institute (www.deming.org).

“The Fourteen Points for the Transformation of Management.”

- Fujimoto, Takahiro. The Evolution of a Manufacturing System at Toyota (Oxford University Press, 1999).

- Nakajima, Seiichi. Introduction to Total Productive Maintenance (Productivity Press, 1988).

Ask the Consultants

Q. Do you have any advice on applying lean principles in a chemical manufacturing laboratory?

A. The application of lean approaches in laboratories shares some characteristics of lean transformations in both clean manufacturing and service environments. Creating a visual workplace is critical, both to maintain a safe and clean work environment and to make “black box” processes easier to see and manage.

Schedules need to be visual as well. And to create flexibility, lab workers need to be cross-trained and multi-skilled. Catherine Converset, senior consultant with Productivity, Inc., advises: “In every lab, you have to discover a new logic to shorten lead time. In manufacturing processes, you usually have one scheduling system for a production unit. But in a lab you might have three or four different sub-labs, and you have to build the bestadapted system for each. In addition, it’s not just that people need to be multi-skilled in all the labs if you want flexibility—they also need to be able to transition into the logic by which you do the scheduling for each.” For a more complete perspective, see The Lean Laboratory.