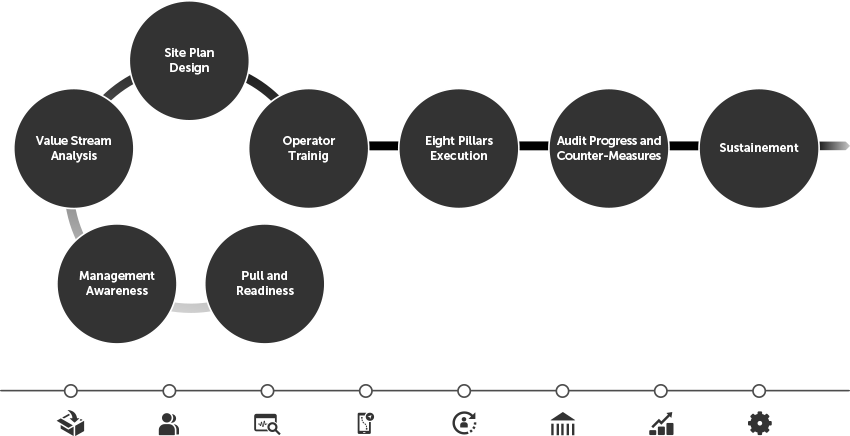

Pull and Readiness

The Productivity Innovation approach relies on creating pull rather than pushing change. As the first step, we work with key leaders to assess readiness and support for TPM. We’ll share business improvement perspectives and strive for understanding of purpose, function, and form.

Management Awareness

In training sessions at your facility, we help site-leadership, managers, and supervisors understand TPM, their role in the transformation effort, and how TPM will enable them and the organization to meet performance goals. It’s here we’ll charter the TPM Roll-Out Team.

Value Stream Analysis

In collaboration with the TPM Roll-Out Team and process owners, we will analyze existing value streams, assess the current state of key equipment operating conditions and plant-wide maintenance practices, and determine the potential impact of improving the six equipment-related losses.

Site Plan Design

Working with site leaders, we’ll develop an integrated site-specific TPM implementation plan that draws on the learning from Pull and Readiness, and Value Stream Analysis.

Operator Training

Through a series of onsite interactive workshops, we teach operators and support personnel about TPM, their role in the program, and the “new normal” for equipment conditions, performance, maintenance, process ownership and routine equipment care.

Eight Pillars Execution

Via Productivity Innovation’s expert training, facilitation, and coaching we’ll help you execute the eight pillars of TPM per your site-specific implementation plan, including autonomous maintenance, maintenance improvement, and focused equipment improvement—all while continuing to develop the competencies of site leadership, support staff, and operators. It’s here where we develop capabilities in applying standard work, predictive and preventive maintenance techniques, problem-solving, waste elimination, EH&S compliance, etc.

Audit Progress and Countermeasures

We’ll establish an iterative process for reviewing the effectiveness of your site plan execution and create countermeasures to close any gaps.

Sustainment

Working with site leaders, we’ll establish standard work routines and Gemba walk practices that allow you to continually experiment with “leaders as teachers”, gauge site plan execution progress, and collaboratively develop and employ countermeasures. Productivity will continue to assess site plan execution progress quarterly and provide insight to help you sustain the efforts and the “new normal” organizational culture.

Swift Return on Investment

At Productivity Innovation, we know TPM! All of our consultants and trainers have real-world implementation experience and are ready to put their knowledge to work for you.

Implementation of TPM, while a long-term endeavor, will provide a swift return on your investment. Now is the time. Contact us to learn more about how we can partner to implement a world-class Total Productive Maintenance program in your facility.