Value Stream Management in Services

Value Stream Management is a method for analyzing, improving and managing processes –from end-to-end — to eliminate waste and synchronize administrative activities in order to reduce time and costs.

Used by the most advanced companies, Value Stream Management enables a comprehensive approach to establishing service flows that will radically enhance the performance of a company’s services.

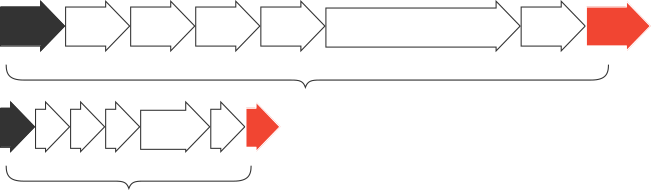

This Lean Value Stream Management process aims to identify and eliminate interruptions (waste), and act as a visual ‘performance improvement plan’ guiding individuals, teams, and project managers through a systemic site transformation.

ELIMINATE SILOS – Transitioning from a silo culture to a Value Chain culture.

Establishing a dialogue between departments to provide better customer service by breaking down walls (silos) is paramount to success.

To meet customer demand, it is necessary that all members of the organization share a common customer-focused vision and a good understanding of the customer-supplier relationship. After all, every organizational function/department is both a supplier (to the next process in the chain) as well as a customer (of the previous one).

Developing a clear and cross-functional perspective of the organizational value-chain commits each function/department to act in ways that optimize the whole. Quality of service to the end customer is ultimately accomplished by improvement in lead-time, process capacity, and reliability all along the value chain.

Identifying Waste and Guiding Systemic Transformation

Using Value Stream Management, a method adopted from the Toyota Production System, we can help you to visualize, define, and improve end-to-end processes by establishing clear process owners, developing customer focused performance indicators and identifying and eliminating all non-value-added activities. This will allow your organization to:

- MANAGE your ability to respond to customers.

- CREATE a system for time management and work balancing among staff.

- INTRODUCE standardization to repetitive activities.

- DEVELOP cross training/multi skilling.