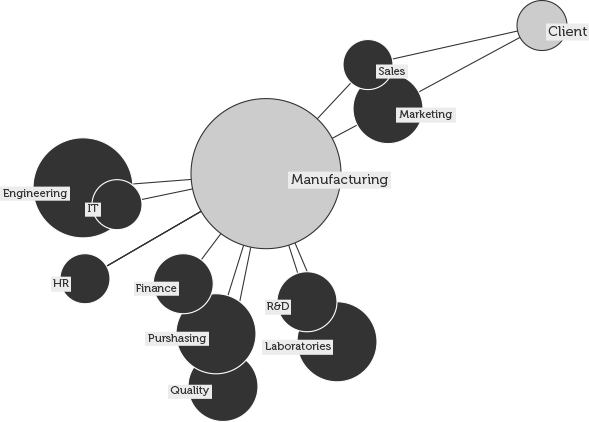

In both Manufacturing and Service environments, the overall company performance is linked to the organization’s ability to establish cross functional processes that run smoothly and effectively for the customer and for the organization.

To accomplish this, it is necessary to expand the improvement efforts in your production processes to your upstream and downstream value chain:

- Reduce new product development process lead time: from R&D to manufacturing.

- Establish a short and reliable order-to-cash process.

- Develop focused and efficient marketing activities to generate new ideas and increase capacity for additional product promotional campaigns.

- Reduce waste in HR processes: reduce recruitment lead time, streamline the on-boarding process, simplify administration functions to provide better service and free up time to allow HR to better support the organization’s transformation efforts.

- Simplify financial processes to improve reporting reliability, on time delivery (faster month-end closing), and their performance as a support service for the overall organization.

- Improve Quality Assurance and Control to accelerate analysis and product release.

At all levels, it is about simplifying, thinking differently, and engaging in dialogue between functions, (reducing reliance on email communication!). It is a process of measuring performance, finding areas for improvement, working together to find solutions, and then starting that process over again.

Productivity Innovation provides our clients with systemic transformation solutions encompassing both the technical and cultural development needed for success. We assist manufacturing administrators in the identification and improvement of key processes while developing the management system necessary to sustain long-term operational effectiveness.

Our approach ensures all improvement initiatives are tied directly to the organization’s strategic objectives and that ownership of the improvement process remains with our clients.

Case Study

LEAN OFFICE IMPLEMENTATION

Company: New England Newspaper Company

Engagement: 3 years

Objective: Implementation of lean in administrative/office operations

Approach:

- Facilitate lean strategy planning and policy deployment process

- Implement a project management process

- Certify 20 Lean Managers

- Lead improvement methodology training events to achieve critical mass

- Design and position a lean audit and counter-measure process

Outcome: Reduced overtime by 10%; Improved labor cost per 100,000 pages by 5%; Achieved an average of 1,144 incremental improvements per year; Improved revenue by employee by 10%; Achieved on-time delivery goals of 98.5%; Achieved overall Scorecard savings of $1,000,000.

Case Study

SAMPLE TRANSACTIONAL PROJECTS

- Cut accounts receivable process time by 33%

- Increased quotation capacity by 40%

- Reduced IT support action item closure time by 25%

- Reduce accounts receivable and accounts payable labor cost by 30%

- Implemented a direct communications program to continuously broadcast company DNA

- Reduced product development quotation time from ›3 to ‹1 day

- Reduced Design Engineering time-to-market from 224 hours to 50 hours

- Shortened the product engineering order processing time from 17 days to 8 days

- Reduced invoicing process time from 22 hours to 8 hours

- Cut the ordering processing time for key customer components by 60%

- Reduced global sales order quotation and order entry process from 10 days to 3 days

- Month-end trial balance (closing) from 5 days to 2 days

- New product launch from 55 days to 15 days

- Reduced customer pricing revision procedure from 77 days to 2 days

- Sales order through engineering design and pre-trial process reduced from 5 days to 1 day